Email Us :

labcompanion@outlook.com-

-

Requesting a Call :

+86 18688888286

Two-zone(Basket Type) Cold and Thermal Shock Test Chamber is a device designed to replicate a range of environmental conditions a product might face throughout its lifespan. It features two distinct compartments: one for hot and one for cold environments. The hot compartment is heated by a heating element, while the cold compartment is chilled by a refrigeration unit. Each box’s temperature is independently controlled, enabling the creation of various temperature scenarios. Products are placed inside and exposed to alternating hot and cold conditions to simulate thermal shock, which is especially critical for electronic components sensitive to temperature fluctuations. This chamber is also valuable for testing product durability under extreme temperatures, relevant for industries such as aerospace and automotive. In essence, the Two-zone(Basket Type) Cold and Thermal Shock Test Chamber is crucial for product testing and quality assurance, ensuring that items can endure the environmental stresses they will likely face in real-world applications.

Item No :

TS2-12-55AOrder(MOQ) :

1Product Origin :

ChinaColor :

WhiteTwo-zone(Basket Type) Cold and Thermal Shock Test Chamber

Parameter and Specification:

|

Model |

TS2-12-55A |

|

Power Source |

AC 380 V, 50/60 HZ, 3 phase 5 lines |

| Rated Current |

AC 9A , 6KW |

|

Test Tank Temperature Range |

-70℃~200℃. |

|

Temperature Shock Range |

-55℃~125℃ |

|

High Temperature Tank Temperature Setting Range |

60℃~200℃. |

|

Low Temperature Tank Temperature Setting Range |

-70℃~-10℃. |

|

High Temperature Tank Heating Time |

RT~200℃≤ 50/min(When the RT at10~30℃). |

|

Low Temperature Tank Cooling Time |

RT~ -70℃ ≤80min(When the RT at10~ 30℃). |

|

Temperature Stability |

±0.5℃. |

|

Temperature Uniformity |

±2.0℃. |

|

Recovery Temperature Time |

-55~125℃ ≤ 5min(Plastic IC load 1.5KG) |

|

High and low temperature impact constant temperature time is more than 15 min |

|

|

Internal Dimension |

W382*H148*D230(mm) |

|

External Dimension |

W860*H1810*D1500(mm) |

|

Suitable Environment Temperature |

5~30℃ |

|

Controller Type |

C100 |

|

Compressor Model |

ZF06KQE*2 |

|

Refrigerant |

R-404A/R23 |

|

Thermoelectric Heating(H) |

3KW |

|

Thermoelectric Heating(L) |

2.5KW |

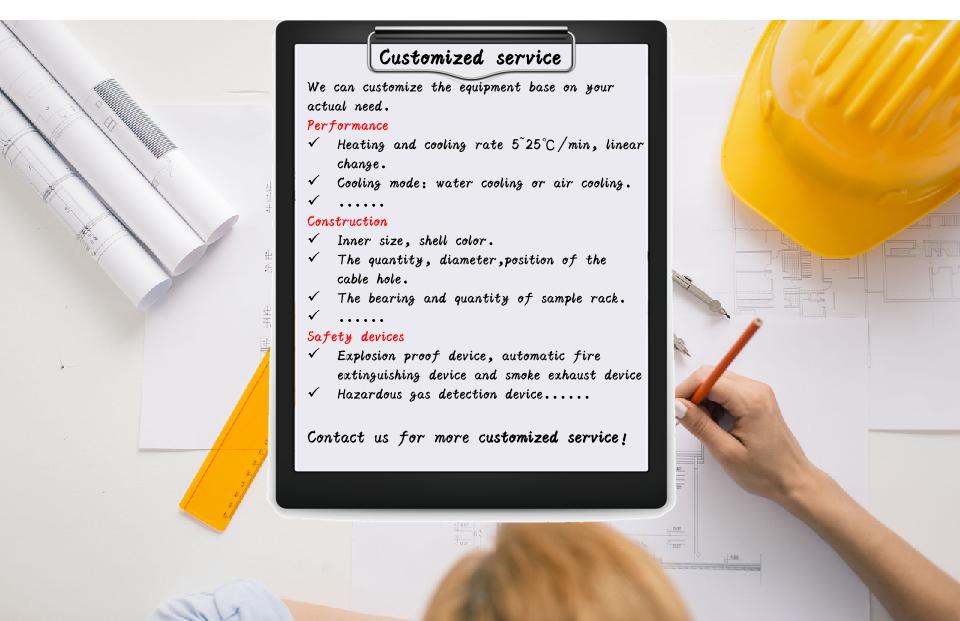

Customized Environmental Chamber

Machine Appearance:

Front and side of the machine

|

Number |

Name |

Illustration |

|

1 |

Three-color light |

Green means running, yellow standby, red fault |

|

2 |

Control panel |

An operation panel for machine controlling |

|

3 |

Power switch |

Used to connect the device and cut off the power supply |

|

4 |

Door lock |

Pull the handle door up with your hand to open it |

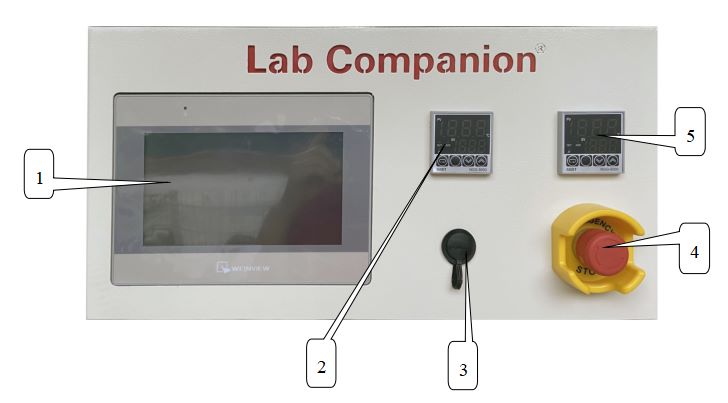

Control panel

|

Number |

Name |

Illustration |

|

1 |

The controller |

Touch screen programmable controller (Refer to controller manual) |

|

2 |

Overtemperature setting (H) |

Set the upper temperature limit in the high temperature zone |

|

3 |

USB port |

Used to copy curves or document-related data |

|

4 |

Emergency stop switch |

Used to connect the device and cut off the power supply |

|

5 |

Overtemperature setting (L) |

Set the upper temperature limit in the low temperature zone |

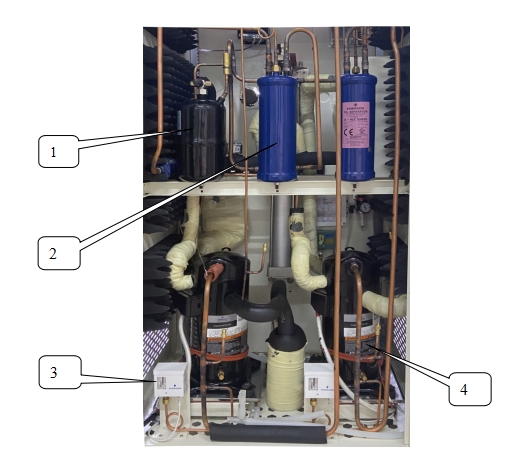

The cooling machine room

|

Number |

Name |

Illustration |

|

1 |

Liquid storage tank |

Storage of refrigerant |

|

2 |

Oil separator |

Separate refrigerant and chilled oil |

|

3 |

Pressure protection controller |

When the pressure in the pipeline is too high or too low, the controller will alarm |

|

4 |

Compressor |

Compression refrigeration |

Environmental Test Chamber Price