Email Us :

labcompanion@outlook.com-

-

Requesting a Call :

+86 18688888286

Environmental conditions have a great influence on the functionality and reliability of the electronic components, devices and systems. A normal temperature test is often not sufficient to detect latent weak points as quickly as possible. Samples must be subjected to multiple, shock like temperature changes. With thermal shock test chamber extremely fast temperature changes from –55 °C to +150 °C can be achieved. This helps you to reduce early failures and to increase the reliability of your products. Reproducible, certified and under accelerated conditions.

Item No :

TS2-60-40AOrder(MOQ) :

1Product Origin :

ChinaColor :

WhiteTechnical Features:

|

Dimensions (mm) |

Width |

Height |

Depth |

|

Useful |

460 |

350 |

300 |

|

Overall |

1006 |

2120 |

1800 |

Temperature and humidity range:

Test tank temperature range: -70℃~180℃.

Thermal shock range: -40℃~150℃

Temperature setting range of high temperature tank: 60℃~180℃

Temperature setting range of low temperature tank: -70℃~-10℃.

High temperature tank heating time from RT (room temperature) to 180℃: ≤ 45/min

Low temperature tank Cooling time from RT (room temperature) to -70℃: ≤50min

Temperature stability: ±0.5℃.

Temperature uniformity: ±2.0℃.

Temperature recovery time from -40 to 150 ° C: ≤ 3min(no-load)

The constant thermal shock time of high and low temperature is more than 15 min

Standard conditions of use:

Use environment temperature: 5~30℃

Other parameters:

1. Controller model: Q8 color touch screen

2. Compressor model: ZF13KQE*2

Refrigerant: R-404A/R23

3. Temperature electric heating (H) : 10.8 KW

Temperature electric heating (L) : 7.2 KW

Power supply specifications:

AC 380 V, 50/60 HZ, 3 ∮ 5 wire

Rated current:

AC 27 A, power 18 KW

This machine is dedicated to the above marked power supply, please use according to the rated power distribution. If the use area is changed, please contact our company. Service phone 400-628-2786.

Construction of Two-zone Thermal Shock Test Chamber:

1, Construction mode of environmental test chamber:

Environmental test chamber is composed of a high temperature test chamber located at the upper end, a low temperature test chamber located below, a freezer cabinet located at the back and a home appliance control chamber (system software) located on the right. In this way, the shell occupies a small area, compact structure, beautiful appearance design, the freezer unit is placed in a separate generator chamber body, in order to reduce the vibration and noise of the freezer unit operation on the environmental test chamber harm, in addition to the installation and maintenance of the generator set, the household appliance operation panel is placed on the right panel of the environmental test chamber to facilitate the operation of the actual operation;

2, Shell surface raw materials: cold-rolled plate, surface electrostatic powder spraying solution;

3, The shell cavity raw materials: imported stainless steel plate (SUS304);

4, Thermal insulation material: heat resistant hard plastic polyamine ester foam + foam glass plate;

5, The door: single door, equipped with double silicone rubber sealing and sealing rubber strip heating equipment, under the self-limiting temperature heating zone, to avoid the experiment essence and frost;

6, Test rack: move up and down left and right sliding type stainless steel plate test rack. The pneumatic double-effect cylinder shows a stable and symmetrical driving force. The positioning device of the test rack uses an electromagnetic field triggered limit switch;

7, Cable wire installation hole: the upper end of the test rack and the top of the high temperature test chamber is provided with a telescopic cable threading tube.

Touch type programmable temperature and humidity controller

It is temperature and humidity programmable controller which equips with the general control, heating and cooling function by supporting high definition TFT-LCD touch screen and SD card.

Performance:

High accuracy

Precision control with 18bit A/D convertor

TEMP. : ±0.1% of full scale ±1 digit

HUMI. : ±1.0% of full scale ±1digit

Optimizing PID group

Precision control by 6 groups of TEMP./HUMI. and 3 group of temperature only

Specialized controller

As a specialized controller for temperature and humidity, synchronized control system with PT-PT, PT-DCV

Specialized humidity control

Humidity control algorithm implements a stable control according to the equipment size。

Heating cooling control

Separated hardware

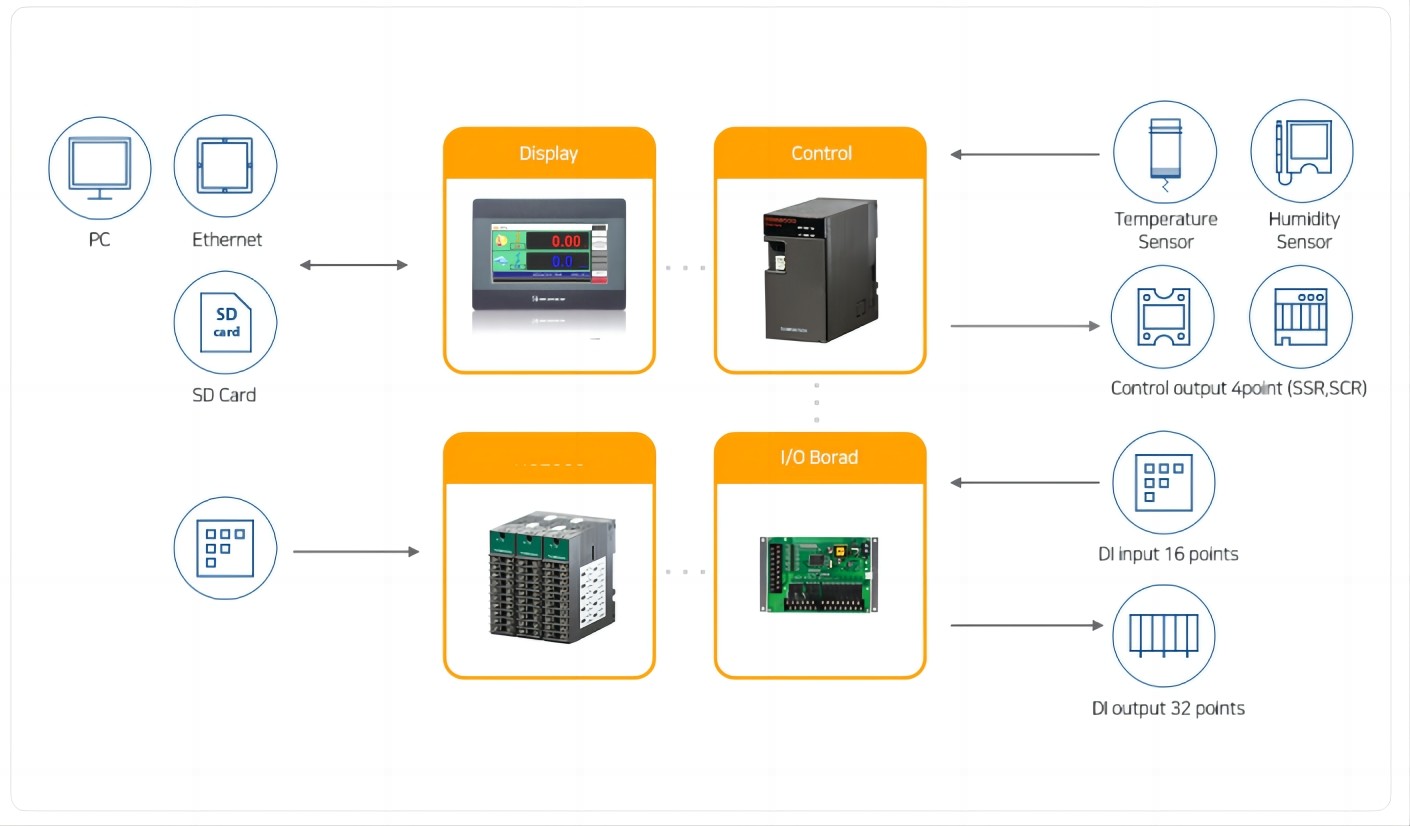

Configuration separated by display, control, and input / output board

Available to mount panel mount and VESA mount