Email Us :

labcompanion@outlook.com-

-

Requesting a Call :

+86 18688888286

Two zone Thermal Test Chamber

【Introduction】

Environmental conditions have a great influence on the functionality and reliability of the electronic components, devices and systems. A normal temperature test is often not sufficient to detect latent weak points as quickly as possible. Samples must be subjected to multiple, shock like temperature changes. With thermal shock test chamber extremely fast temperature changes from –55 °C to +150 °C can be achieved. This helps you to reduce early failures and to increase the reliability of your products. Reproducible, certified and under accelerated conditions.

【Test Standard】

IEC 60068-2-14 Na

MIL-STD-810H, Method 503.7

MIL-STD-883L-1, Method 1010.9

JASO D 014-4

Item No :

TS2-60/120/300Order(MOQ) :

1Product Origin :

ChinaColor :

WhiteLead Time :

30 working days| Model | TS-60 | TS-120 | TS-120P | TS-300 | TS-300P | |

| Test space volume | L | 60 | 120 | 120 | 300 | 300 |

| Mobile basket maximum load | Kg | 20 | 50 | 50 | 100 | 100 |

| Test space size,Height×Width×Depth | mm | 370x380x430 | 410x470x650 | 410x470x650 | 610x770x650 | 610x770x650 |

| Hot chamber temperature range | ℃ | +50~+220 | +50~+220 | +50~+220 | +50~+220 | +50~+220 |

| Cold chamber temperature range | ℃ | -80~+70 | -80~+70 | -80~+70 | -80~+70 | -80~+70 |

| Heating rate of hot chamber1 | K/min | 17 | 14 | 18 | 11 | 23 |

| Cooling rate of cold chamber1 | K/min | 3.7 | 6.3 | 7.5 | 5 | 12 |

| Cold chamber heating rate, single box operation1 | K/min | 3.2 | 2 | 2 | 1.5 | 1.5 |

| Temperature stability2 | K | ±0.3~±1.0 | ±0.3~±1.0 | ±0.3~±1.0 | ±0.~±1.0 | ±0.3~±1.0 |

| Temperature uniformity3 | K | ±0.5~±2.0 | ±0.5~±2.0 | ±1.0~±2.0 | ±0.5~±2.0 | ±1.0~±2.0 |

| Hot/cold chamber transition time | sec | <10 | <10 | <10 | <10 | <10 |

| Recovery time - temperature change test | min | <154 | <155 | <126 | <157 | <158 |

| Hot chamber calibration value9 | ℃ | 125 | 125 | 125 | 125 | 125 |

| Cold chamber calibration value9 | ℃ | -40 | -40 | -40 | -40 | -40 |

1According to IEC 60068-3-5. Increase the rate of temperature change by raising/lowering the hot/cold chamber temperature.

2Effective test space center point.

3Based on setting point: Temperature range -65℃ to +200℃

4MIL-STD-883E, method 1010.9, intensity class D, 4.5 kg lCs were distributed in two sample racks and measured in sample.

5MIL-STD-883J,method 1010.9,intensity class D,12 kg lCs were distributed in three sample racks and measured in sample.

6MIL-STD-883F,method 1010.9,intensity class D,20 kg ICs were distributed in three sample racks and measured in sample.

7MIL-STD-883J,method 1010.9,intensity class F,25 kg lCs were distributed in three sample racks and measured in sample.

8MIL-STD-883 F,method 1010.9,intensity class F,50 kg lCs were distributed in three sample racks and measured in sample.

9Ex-factory measurement

The above performance data is based on ambient temperature of +25℃, rated voltage of 400V/50Hz, no sample, no additional configuration and thermal compensation conditions.

High and Low Temperature Shock Chamber

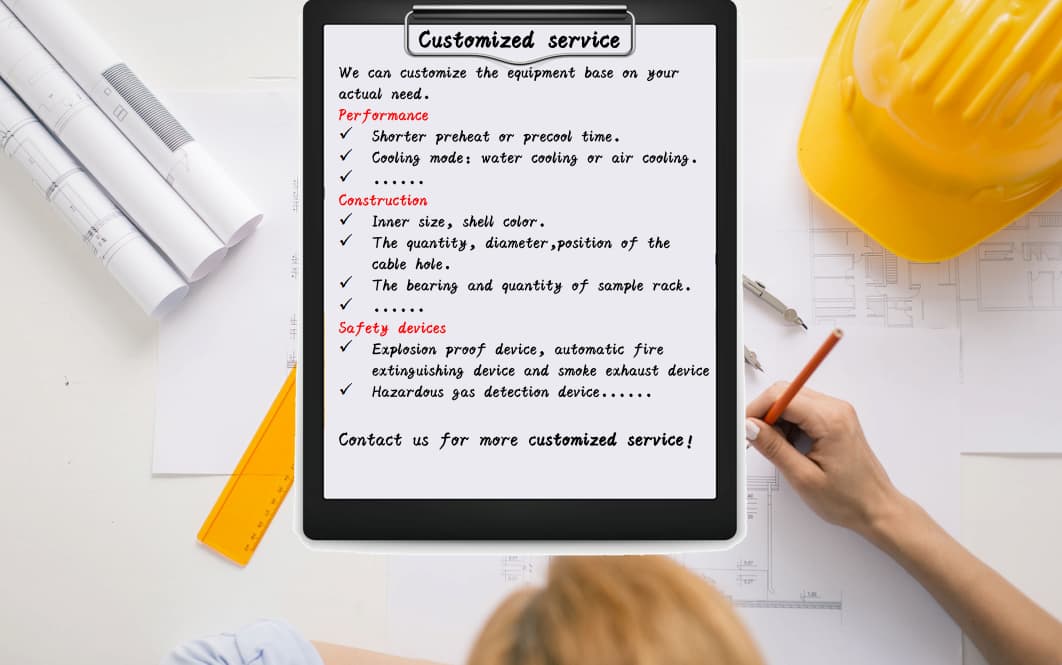

❉Quality assurance: The chamber is designed according to the international standard, core components are all from the global renowned brand.

❉Easy control: 7 inches color touch control panel with large data storage of 1200 days, automatically analyse failure and display measures.

❉Short preheat or precool waiting time and defrosting.

Intelligentized Thermal Chamber

Small volume Thermal Chamber

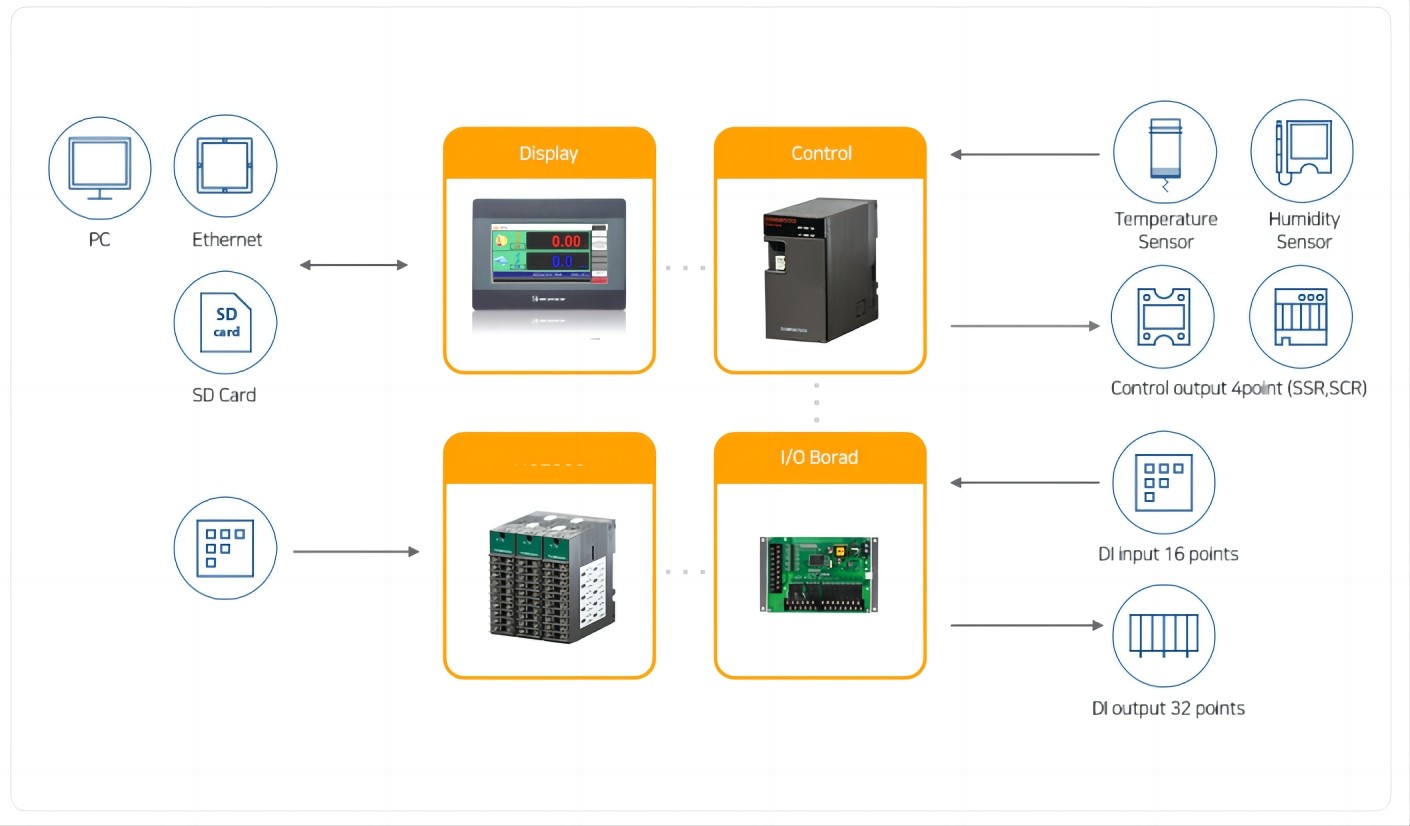

Touch type programmable temperature and humidity controller

It is temperature and humidity programmable controller which equips with the general control, heating and cooling function by supporting high definition TFT-LCD touch screen and SD card.

Performance:

High accuracy

Precision control with 18bit A/D convertor

TEMP. : ±0.1% of full scale ±1 digit

HUMI. : ±1.0% of full scale ±1digit

Optimizing PID group

Precision control by 6 groups of TEMP./HUMI. and 3 group of temperature only

Specialized controller

As a specialized controller for temperature and humidity, synchronized control system with PT-PT, PT-DCV

Specialized humidity control

Humidity control algorithm implements a stable control according to the equipment size。

Heating cooling control

Configuration separated by display, control, and input / output board

Available to mount panel mount and VESA mount