Email Us :

info@lab-companion.com labcompanionltd@gmail.com-

-

Requesting a Call :

+86 18688888286

TC-1000 Thermal Cycle Test Chamber of Lab Companion--"Super Product" of Thermal Cycle Test of Optical Devices

Thermal cycle

Almost all optical devices have to go through thermal cycle tests before leaving the factory.

The coefficient of thermal expansion of each material is not the same, and only under drastic temperature changes can different materials be tested to see whether there is a risk of failure.

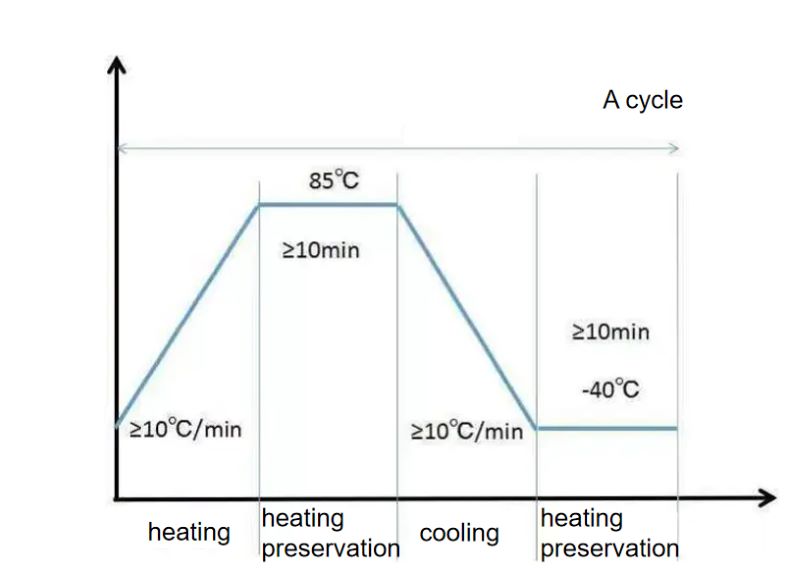

Thermal cycle rises and falls at a rate of at least 10 ° C /min, and at the two temperature points of 85 ° C and -40 ° C, it must stay long enough for the device to reach the room temperature. For indoor optical modules, 100 cycles is OK, and for outdoor optical modules, 500 cycles are required. For a module with a TEC temperature control, keep the TEC on during thermal cycle.

TC-1000 rapid-rate thermal cycle test chamber is a superior product of Lab Companion, which brings product testing to a new stage. From the high-horsepower compressors and high wind speeds in the test area, to the superior graphics/curves demonstrated by the pioneering C100 controller, the TC chamber of Lab Companion has quickly established a new standard in quality and precision. The TC chamber with good performance can make the environment in the chamber and the measured product produce rapid temperature changes, thus greatly reducing the test time and improving the work efficiency of the test. The rapid temperature change also makes the measured product produce greater stress, and thus also improves the stress screening efficiency, which can reach 15 ° C /Min of linear temperature change rate when the load is more than 100Kg, and the temperature deviation in the chamber is ±2.0 ° C during the heating and cooling process.