Email Us :

labcompanion@outlook.com-

-

Requesting a Call :

+86 18688888286

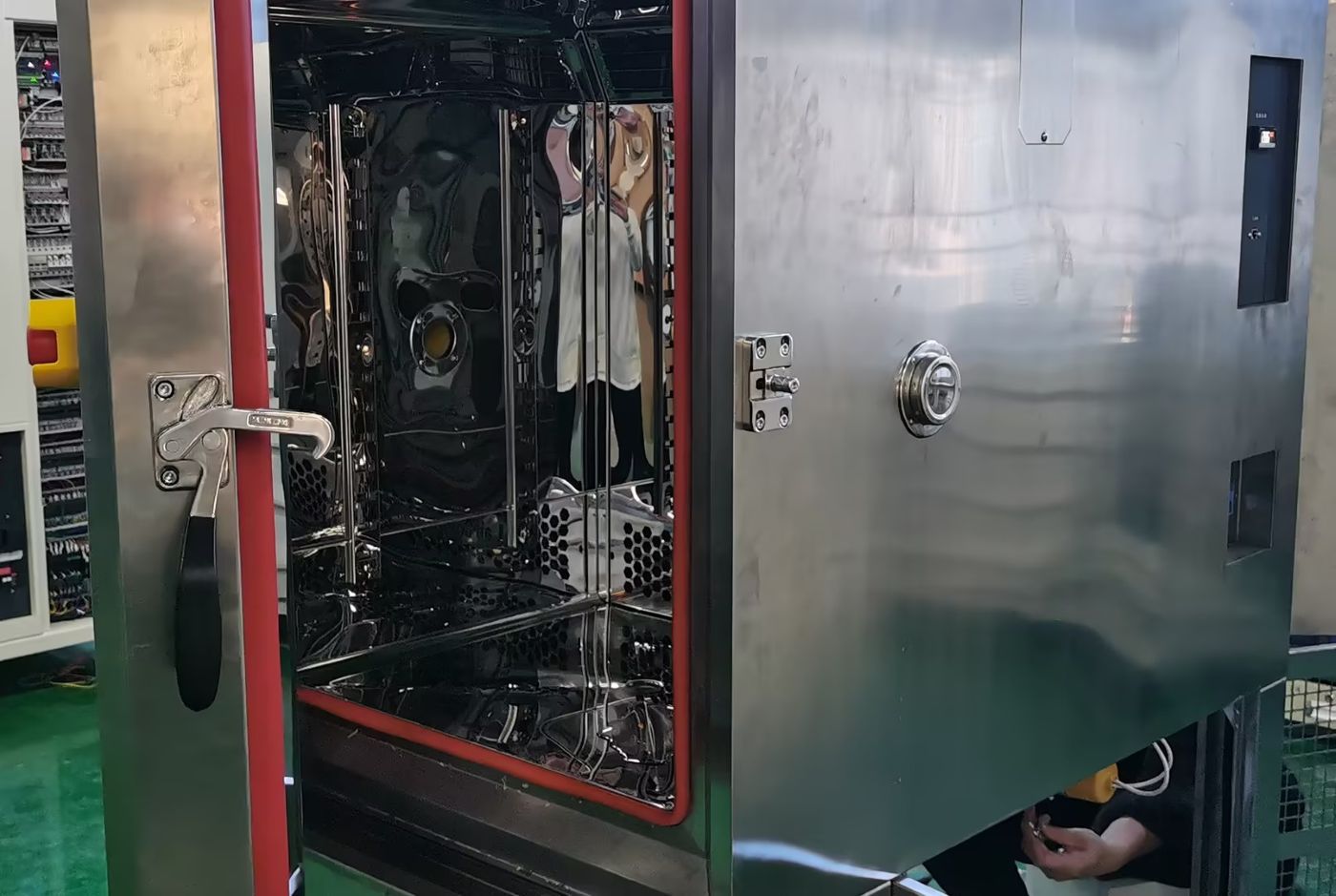

1.Equipment Overview

The Humidity & Temperature Test Chamber, also known as an Environmental Simulation Testing Apparatus, is a precision instrument requiring strict adherence to operational protocols. As a Class II electrical device compliant with IEC 61010-1 safety standards, its reliability (±0.5°C temperature stability), precision (±2% RH humidity accuracy), and operational stability are critical for obtaining ISO/IEC 17025 compliant test results.

2.Pre-Operation Safety Protocols

2.1 Electrical Requirements

2.2 Installation Specifications

Rear: ≥500mm

Lateral: ≥300mm

Vertical: ≥800mm

Temperature: 15-35°C

Humidity: ≤85% RH (non-condensing)

Atmospheric pressure: 86-106kPa

3.Operational Constraints

3.1 Prohibited Environments

4.Commissioning Procedures

4.1 Pre-Start Checklist

5.Operational Guidelines

5.1 Parameter Setting

5.2 Safety Interlocks

6.Maintenance Protocol

6.1 Daily Maintenance

6.2 Periodic Maintenance

Temperature: ±0.3°C (annual)

Humidity: ±1.5% RH (biannual)

7.Failure Response Matrix

| Symptom Priority | Priority | Immediate Action | Technical Response |

| Uncontrolled heating | P1 | Activate emergency stop | Check SSR operation (Vf <1.5V) |

| Humidity oscillation | P2 | Initiate auto-dry cycle | Verify dew point sensor calibration |

| Condenser frost | P3 | Reduce humidity setpoint | Check expansion valve (ΔT 5-8°C) |

| Water level alarm | P2 | Refill with DI water | Conduct float switch resistance test |

8.Decommissioning & Disposal

9.Compliance Standards